Remote locations with no or limited infrastructure are common setup in which construction sites and cultural events must operate. Mobile diesel generators are critical equipment for these industries and their applications, where sources of temporary power are a necessity to sustain the functional operation.

Growing awareness of a negative impact caused by emissions and pollution coming from operating these generators and other equipment powered by IC engines lead to an introduction of legislations classified for non-road mobile machinery (NRMM).

As a result of this legislation manufacturers of equipment powered by diesel engines are obligated to follow Stage Ⅴ standard as a legal requirement for their products. Stage Ⅴ standards is a mandatory requirement, and every engine must accommodate additional exhaust after-treatment technologies to eliminate emissions to the level defined by the standard.

Engines rated more than 56kW require Selective Catalytic Reduction (SCR) and Diesel Particulate Filter (DPF) modules fitted to the exhaust of a generator in order to remove excess NOx and eliminate particles matter emission.

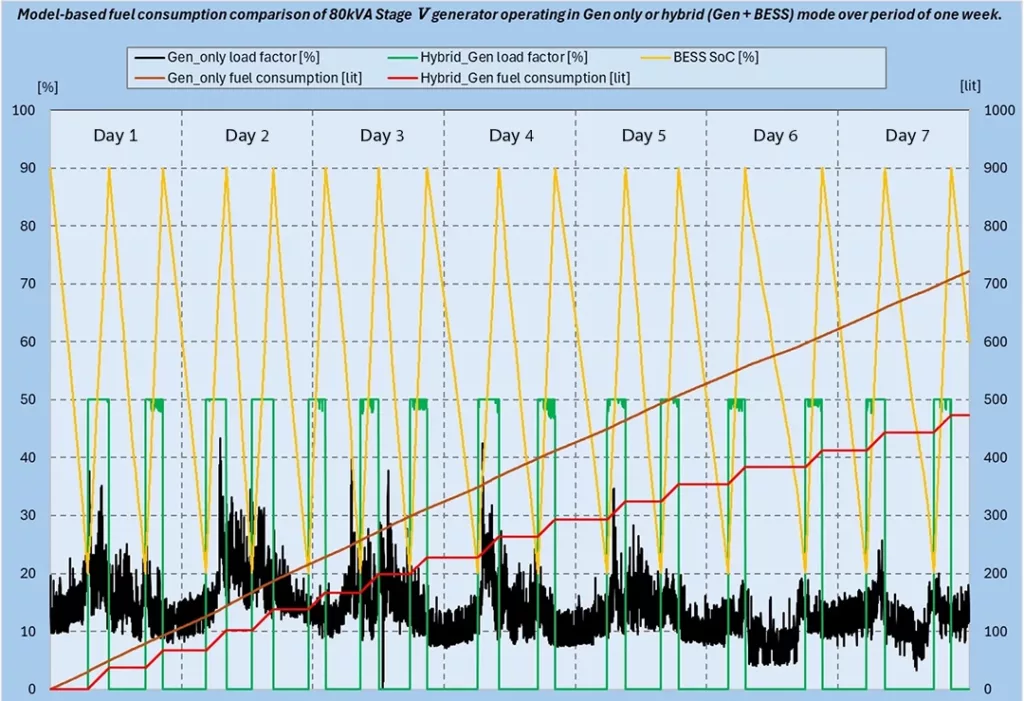

SCR and DPF modules can only achieve optimal functional effectiveness if their operating temperature is typically over 250℃. This means that a mobile generator powered by Stage Ⅴ engine needs to be loaded with a minimum of 50% of its rated power for a considerable amount of time to allow the temperature to build-up. In the world of temporary power, Stage Ⅴ mobile generators predominantly operate 24/7 i.e. on construction sites where constant load of 50%or above is sporadic and in many cases can be as low as 10%-20% over prolong time i.e. during night hours. The working conditions of such generators lead to malfunction of the exhaust after-treatment modules, resulting in emission increase and premature wear of the modules themselves.

To address these issues, the generators’ manufactures or fleet operators in many cases deliberately install ballast (or dump) loads i.e. bank of electric heaters to increase the generator’s load in order to achieve the desirable operating temperature. At first this appears to be an acceptable solution – the required filters performance is achieved, and emission desired level is maintained. On the other hand, undesirably more fuel is burned and wasted. Moreover, the use of ballast load increases CO2 emissions which directly contradicts the main objective of Stage V legislation targeting cleaner and environmentally friendly solutions.

Omni Grid Energy offers an alternative and optimal solution – the generator hybridization by combining Stage Ⅴ mobile generator with battery energy storage system (BESS). Our OmniQube mobile BESS solution not only ensures uninterruptable power supply to the load but also gives an advantage by operating Stage Ⅴ generator at higher loading factor with a maximum overall system efficiency.

In a case of a low load factor – the hybrid system operates in BESS only mode, keeping generator in OFF mode and then starts the generator in order to recharge BESS at high power rate, maintaining load supply till BESS is fully charged and then the cycle repeats.

Our holistic approach to mobile Stage Ⅴ generators hybridization based on expert knowledge of BESS technology and an in-depth understanding of technical system complexity offers best solution on the market while minimizing adverse impact on environment. Thanks to OGE products, the fleet owners and plant rental companies will now be able to provide the most economical and sustainable product and services, allowing power consumers to meet their productivity and operational goals.